Complete Guide to Calibration and Use of TITAN Series Top Camera(New)

Preface

Camera calibration ensures precise design alignment for the machine. This guide walks you through the process to boost accuracy and output quality.

How to import the calibration file

Every machine in the TITAN series has a camera or dual camera, as well as a calibration file. Import the calibration file directly to use the camera.

Tool needed

U disk.

Specific steps

- To import the camera calibration file, we first need to follow the steps shown in the figure below to find the 'External import' entry.

- Next, connect the U disk to your computer.

- Finally, locate the calibration file in the following path and import it.

How to calibrate the camera

It should be noted that the camera of your machine has been calibrated before leaving the factory, and the calibration file has been saved in the U disk. Unless necessary, please skip this camera calibration process, and do not adjust the camera on the machine to avoid deviation in accuracy that requires re-calibration.

Specific steps

- First, connect the machine to your computer.

Use the Ethernet cable to connect the machine and the computer.

For more connection methods, you can refer to the following article.

TITAN Connection Method

- Next, place the plywood on the platform and ensure it is flat and secure—you can use clamps, double-sided tape, or other suitable methods based on your actual equipment. Then, move the laser head to the machine’s zero position and refer to this picture for the correct placement of the plywood and laser head.

- Once the laser head is positioned as shown in the image above, click the Origin button on the touch panel.

- Use the auto-focus function on the touch panel to complete focusing.

- Then, take off the camera cover.

- Adjust the sharpness of the camera.

Put a piece of printed paper on the plywood for adjustment. Then open the built-in camera function of the computer.

The machine's camera was calibrated for clarity before leaving the factory and fixed with blue glue. Refocusing is only necessary when the image is very blurry.

You can open the right side door of the machine to find the camera cable.

Left camera | Right camera |

- Rotate the gear counterclockwise to loosen it a bit, and then the lens can be rotated.

- Close the top cover and adjust the sharpness of the camera by rotating it.

To ensure the camera’s sharpness is adjusted to the best, it is recommended to use such an adjustment method: first, open the front door panel, then close the lip cover to create enough space for your hand to reach in and make adjustments.

- Keep adjusting until the image is clear—you should be able to see the text on the paper distinctly—then turn the gear clockwise to fix the camera in place.

- Before performing this step, make sure that your machine is successfully connected to your computer.

- Next, go to Settings >> Camera >> Camera-Top>>Preview.

Signal camera | Dual camera |

- After that, click the 'Calibration Wizard' button to start the camera calibration process. In the pop-up 'Camera Calibration Wizard' window, select 'Top Camera'.

- Select the corresponding device model in the camera calibration software and click "Upload" to upload the calibration file.

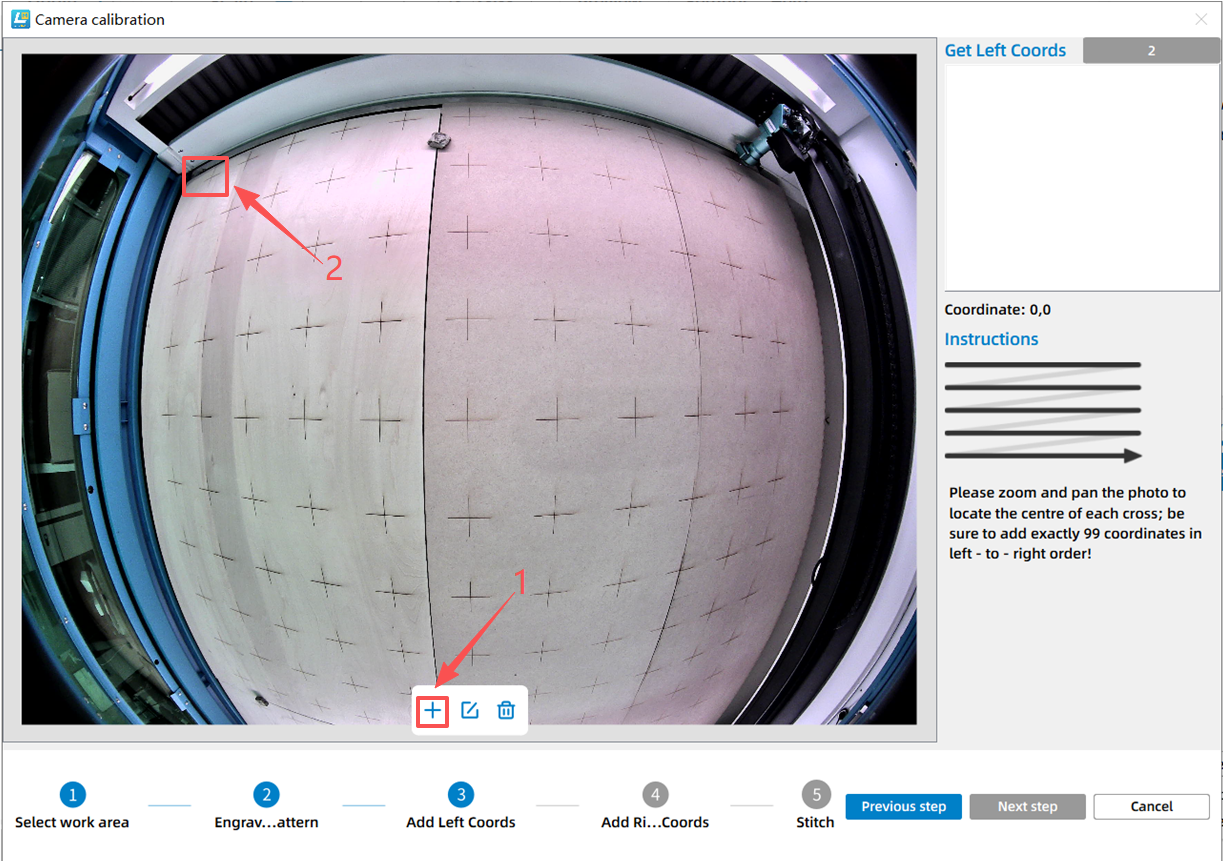

When adding crosses, if you need to modify one, click the edit function and select the target cross. Once the cross changes from red to green, you can move or delete it.

After adding all left cross coordinates, click "Next step" to proceed to add right cross coordinates.

It is necessary to save and back up camera calibration files created for different devices under different software versions. Additionally, if the machine's IP address changes, after reconnecting to the machine, you need to re-import the camera calibration file.

How to use the camera

Specific steps

- First, ensure that your camera is calibrated or that the calibration file has been imported.

- Next, click "Camera" to get real-time images, and place the target pattern on the work platform.

- Then, click the "Full preview" to update the live view.

- After that, click "Extraction" to capture your desired image; once captured, click "Extract" to confirm.

- Subsequently, close "show preview in canvas".

- Next, remove the paper that was just placed on the work platform, then re-enable "show preview in canvas", and click "Full preview" to update the canvas content.

- Finally, move the pattern you just extracted to the desired position, then click "Start" to begin processing.

The correct processing parameters must be set before starting work.

The correct processing parameters must be set before starting work.Still need help?

For specific technical questions or help requests, please open a Ticket with picture or video, so our Support team can assist you ASAP.

For the information provided in the ticket, please refer to this link:

Help Tech Support Troubleshoot Faster

End.

Related Articles

Complete Guide to Calibration and Use of TITAN Series Top Camera

Preface Camera calibration ensures precise design alignment for the machine. This guide walks you through the process to boost accuracy and output quality. How to import the calibration file Every machine in the TITAN series has a camera or dual ...Complete Guide to Calibration and Use of TITAN Series Machine CCD

Preface This guide provides clear instructions on how to import calibration files, calibrate the CCD, and use the CCD for the TITAN series machines. By following these steps, you can ensure the proper functioning and accuracy of the camera system. ...Complete Guide To TITAN Series Laser Alignment

1 Purpose ⚠️ THIS DOCUMENT IS ONLY APPLICABLE TO TITAN PRO SERIES The purpose of this document is to provide detailed, step-by-step instructions for aligning the optical beam paths of TITAN PRO Series laser systems. This procedure ensures the Fiber ...TITAN Series User's Manual

TITAN Series User's Manual Please see attached. Still need help? For specific technical questions or help requests, please open a Ticket with picture or video, so our Support team can assist you ASAP. For the information provided in the ticket, ...Complete Your First Project with Titan PRO

Preface This article focuses on how to complete your first project using the TITAN Pro machine. The operating steps are the same for the TITAN. Connect the Machine to the Software Make sure the machine is connected to LightBurn or LaserMaker. The ...